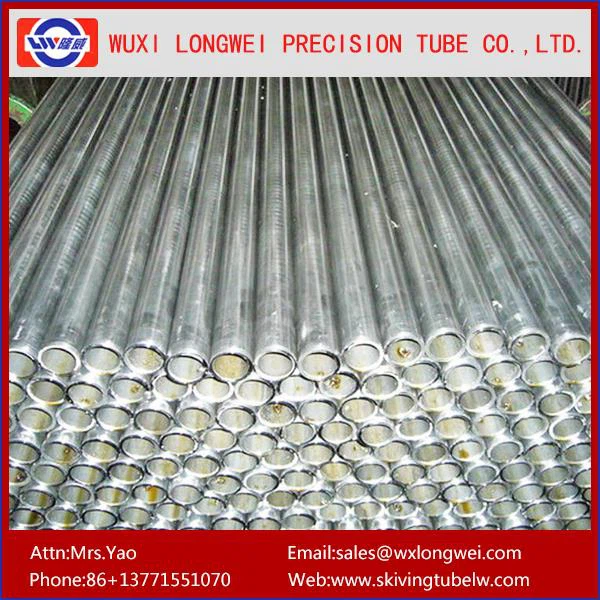

Small Diameter Shaped Steel Tube

steel tube structure: Shaped steel tube for economical section. Including cross section, non-circular, equal wall thickness, variable wall thickness, varying diameter and wall thickness along the length, cross section symmetry and asymmetry, etc. Such as square, rectangle, cone, trapezoid,...

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Introduction

Small Diameter Shaped Steel Tubes are among the most widely used products in the construction and manufacturing sectors. They are made of high-quality materials, which guarantee their durability, reliability and resistance to wear and tear. As a manufacturer, I offer a range of products to merchants, and Small Diameter Shaped Steel Tubes are one of the most popular products.

These tubes have a small diameter, which makes them ideal for use in applications where space is limited. They can be used in a variety of industries, including construction, automotive, aerospace, and many others. In this product introduction, I will explain the different aspects of Small Diameter Shaped Steel Tubes that will make them a popular choice among merchants.

Design

Small Diameter Shaped Steel Tubes are designed to meet the specific needs of different industries. They come in a wide range of sizes, shapes, and configurations. As a manufacturer, I can create customized designs based on the specific requirements of the merchant. The design process is done using computer-aided design (CAD) software, which ensures accuracy, consistency and quality of the final product.

Materials

Small Diameter Shaped Steel Tubes are made from high-quality steel materials, which are carefully selected based on their properties such as tensile strength, hardness, and toughness. The use of high-quality materials makes the tubes resistant to corrosion, wear and tear, and other harsh environmental conditions. The tubes can also withstand high pressures and temperatures, making them perfect for use in challenging applications.

Applications

Small Diameter Shaped Steel Tubes are used in a wide range of applications across different industries. In the construction industry, they are used to create frames, supports, and structures for buildings, bridges, and other infrastructure projects. They are also used in the automotive industry to create frames, suspension systems, and other components.

In the aerospace industry, Small Diameter Shaped Steel Tubes are a critical component of aircraft engines, landing gear, and other systems. They are also used in the manufacture of medical equipment and devices, appliances, and machinery.

Advantages

Small Diameter Shaped Steel Tubes offer several advantages over other types of materials such as aluminum, copper, and plastic. Steel is a highly durable and long-lasting material that can withstand extreme temperatures and pressures, making it ideal for use in harsh environments. The tubes are also highly resistant to corrosion, ensuring that they remain in excellent condition for an extended period.

Another advantage of Small Diameter Shaped Steel Tubes is their malleability. Steel is highly malleable, which means that it can be manipulated into different shapes and sizes, making it ideal for use in a wide range of applications. This malleability also makes it easy to create customized designs that meet the specific requirements of the merchant.

Conclusion

Small Diameter Shaped Steel Tubes are a highly versatile and durable product that is widely used across different industries. They are made from high-quality materials, designed to meet the specific needs of different applications and offer several advantages over other types of materials. As a manufacturer, I am committed to producing high-quality Small Diameter Shaped Steel Tubes that meet the needs of merchants both in China and around the world. With our expertise, precision engineering, and dedication to quality, we are confident that our Small Diameter Shaped Steel Tubes will provide optimal performance and durability for all applications.

steel tube structure:

Shaped steel tube for economical section. Including cross section, non-circular, equal wall thickness, variable wall thickness, varying diameter and wall thickness along the length, cross section symmetry and asymmetry, etc. Such as square, rectangle, cone, trapezoid, spiral and so on.

Special shaped steel pipe can adapt to the special conditions of use, save metal and improve the labor productivity of parts manufacturing. It is widely used in aviation, automobile, shipbuilding, mining machinery, agricultural machinery, building, textile and boiler manufacturing and so on. The methods of producing special tubes are cold drawing, electric welding, extrusion and hot rolling, among which cold drawing method has been widely used.

Shaped steel tube application:

Special shaped seamless steel tubes are widely used in various structural parts, tools and machinery parts. Compared with the circular tube, the special-shaped tube generally has larger inertia moment and sectional modulus, and has greater bending and torsion resistance, which can greatly reduce the weight of the structure and save steel.

Shaped steel tube Molding method:

Shaped steel pipe, special-shaped steel tube bending forming, this form, which is commonly known as bending. Special shaped steel tube bending is divided into two kinds, one kind of real bending, another empty bending.

The true bending of square tubes is compacted, and then the bending of the inner and outer roller tubes, shaped steel tubes inside and outside the wall compaction is a two-way process. The real bending rectangular tube has the advantages of solid bending will be relatively small, and the formation of a more accurate, and in the production time, as long as the use of roller is accurate, and the angle shaped steel tube forming steel pipe internal rebound after the more accurate, we can ensure accurate.

Production of air bending of rectangular tube, the outer wall of the tube outside and square shaped steel tube and roller, and metal bending, bending of the empty time, pipe bending curve will produce a certain compression, so the compression effect, zigzag line longitudinal variable length, rectangular tube bending metal will become thick air compression bending. Or thickening effect.

The two production methods, two basic ways of rectangular tube production square and special-shaped steel tube molding, according to the needs of different products, select the appropriate process configuration. It should be noted that, when stretched and compressed, the impression on the quality of the product, or lead to square tube deformation.

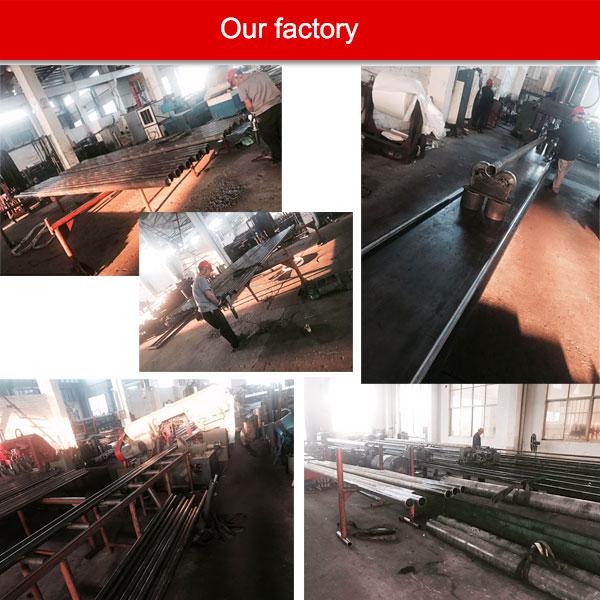

Trict contract auditing invloved all departments to assure the feasibility of each order.

Process design and validation before bulk production.

Strictly control on all raw and auxiliary materials, All raw materials reach the world advanced level.

On-site inspection to all processes, inspection record keep traceable for 3 years.

Please feel free to send us your detailed requirements, you would be satisfied with our service